Case studies

AngloGold Ashanti Ltd, Obuasi Mine

Project Summary

|

Project Value: |

£1,300,000 |

|

Service: |

Design, Manufacturing & Supply |

|

Duration: |

15 Months |

Background

AngloGold Ashanti is a global gold mining company with 20 operations on four continents. The Obuasi mine is located in the Ashanti region of Ghana where mining operations are primarily underground, to a depth of 1.5km. In recent years, the Obuasi mine has faced significant operational challenges with ageing plant requiring repair or replacement.

Quartzelec were awarded the contract to replace the existing DC Winder Motor on the KMS 1 Shaft at the Obuasi Mine. As the original motor was supplied by a third party, a full site audit was required to establish all the critical dimensions and machine parameters. During the audit, it was noticed that the existing motor was in urgent need of major remedial works.

The Project

Quartzelec were responsible for the design, manufacture, supply and delivery of a Quartzelec DLC120M78 DC Winder Motor, both mechanically and electrically interchangeable with the existing Motor as a complete assembly with an increased rating of 3,600Kw at 55.7 rpm. The replacement motor was required to have exactly the same footprint as the original and be capable of operating under both thyristor and MG Set Supply.

Because the original motor had primarily been manufactured to NCB (National Coal Board) Winder Rationalisation standards, equivalent designs were found in the Quartzelec archives. This also provided a guide to the mechanical interfaces which were then checked / confirmed during a full site audit.

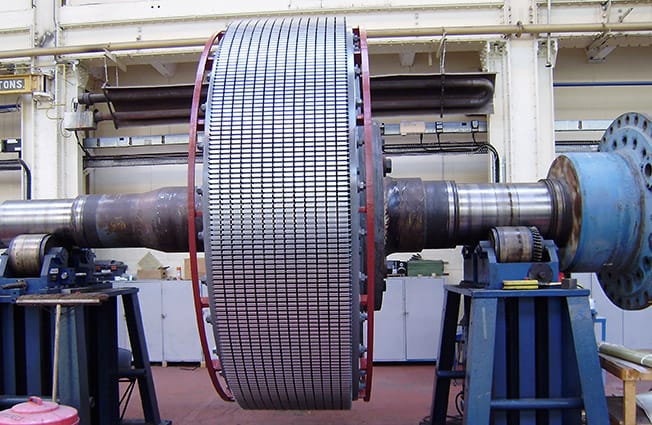

The motor was shunt wound, separately excited, fully compensated and supplied complete with a Wound Overhung Armature, Split Laminated Magnet Frame, Tandem Radial Brushgear and Embedded Temperature Detectors (RTD's) - 4 off in compole coil. The motor was manufactured using modern materials and manufacturing practices and because of this, Quartzelec were able to offer the uprate over the original nameplate rating in excess of 35%.

On completion of manufacture the motor was subject to Quartzelec’s standard testing procedures which included static tests, rotational tests and electrical characteristics check. In addition, the customer witnessed simulated full load rotational testing of the motor which proved to be a major success factor.

The motor was packaged, shipped to site and based on the successful results of the witness testing, the motor was approved and accepted by the customer. Coupled with other improvements across the mine, the new motor should help increase production across the entire site.

Quartzelec’s in house DC design capability provided a distinct advantage over competitors as Quartzelec were able to offer guarantees based on experience and similar designs.

#UnparalleledInEngineeringServices

Follow us on Facebook, X & LinkedIn

CS59

Rue des Finettes 54

1920 Martigny

Switzerland