NEWS

Keeping the wheels turning in the mining sector

30 January 2014

Quartzelec uses its expertise to produce winding motors for mining operations in Ghana and Australia.

The global mining sector is totally reliant on DC winding and lifting motors but the need to keep these huge pieces of plant serviced and operational is a mamouth task. Over the past five years Quartzelec, a leading UK independent electrical engineering group, has heavily invested in infrastructure and built an enviable reputation for cost effectively maintaining and even improving aging winding plant.

In early 2011, for example, a mine in Ghana, which operates at depths of around 1.5km, faced significant operational challenges and awarded Quartzelec a contract to replace an existing DC winder motor. A full on-site audit was initially undertaken to establish the critical dimensions and machine paramiters as no drawings or designs were avilable and this identified the urgent need for major remedial works. The replacement motor not only had to have exactly the same footprint as the original but the customer required the replacement to be more powerful and be capable of operating under both thyristor and MG Set supply.

“By drawing on our experience and accessing our vast archive we were able to identify an equivalent design on which to base the replacement as the original motor had primarily been manufactured to National Coal Board winder rationalisation standards,” explained Neal Parkin at Quartzelec. “This also provided us with a guide to the mechanical interfaces which was then confirmed during the full site audit. By using modern materials and manufacturing practices, combined with our in-house DC design capabilities, we were able to increase the performance of the new motor by over a third which made the customer really happy.”

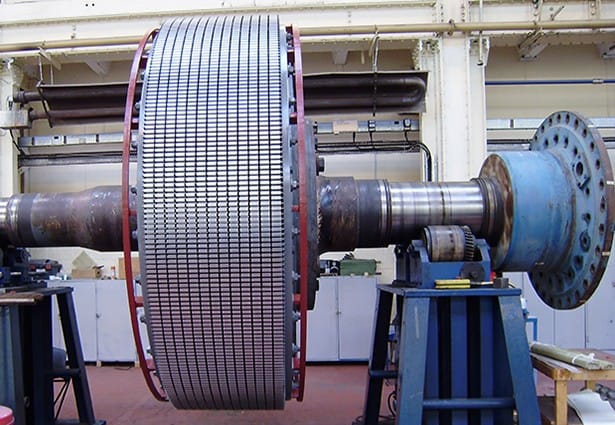

The new DC winder motor is both mechanically and electrically interchangeable, as a complete assembly, with the existing motor but also has an increased rating of 3,600Kw at 55.7 rpm. The motor is shunt wound, seperately excited and fully compensated and was supplied complete with a wound overhung armature, split laminated magnetic frame and tandem radial brushgear. The motor also features four embedded temperature detectors within the compole coil for improved performance monitoring.

Another replacement winder motor project was for a mine in Australia. One of the most productive single mines in world history, it was opened in the 1920s and today features two separate mining and processing streams with over 6m tonnes of copper ore and 4.6m tonnes of silver, lead and zinc ore being extracted in a year.

Quartzelec was first engaged in 2007 to undertake a full inspection of the winder motor as the owners had become increasingly concerned about the age and its future reliability. Of strategic and financial importance the motor has been bringing copper ore up more than 1,500m to the surface since 1972. The eventual solution, as having the motor rewound was impractical due to the extended downtime that would be needed, was to manufacture a replacement motor that would provide at least another 25 years of reliable operation.

The customer also specified that the new winding motor should have exactly the same footprint as the original and that the motor frame and armature be fully interchangeable and be kept consistent with the original so that the existing field winding spares held in-stores could be used in the event of an emergency. the contract required for a minimum 10% improvement in performance over the existing 5.6MW motor.

The project time was 12 months with the replacement horizontally mounted, shunt compensated DC machine, frame size DLC144/75, winding motor being designed and fabricated in the UK and rated at 6750kW, 1000 Vd.c., 7220A and running at 54 revolutions per minute. The motor comprised a laminated magnet frame, armature, commutator and brushgear and was cooled by forced ventilation from an external supply. Prior to delivery, the motor was fully tested by Quartzelec’s experienced engineers and the customer also witnessed simulated full load rotational testing which was a major success prior to it being packed and shipped to the other side of the world.

“In this instance we not only designed a fabricated a new motor with an identical footprint and field configuration as the original which saved the customer having to secure additional spares but we were able to boost the rating by over 20% to 6.75MW,” stated Alan Harley. “At Quartzelec we continue to draw on our global experience and extend our enviable reputation for delivering cost effective solutions that help the global mining industry meet its needs. We constantly travel the globe advising customers on maintenance and safety issues as well as undertaking totally new design projects.”

A leading engineering authority with an annual turnover in excess of £50m, Quartzelec has over 80 years experience and technical expertise in the design, manufacturing, installation, maintenance and service for electrical motors, generators and systems.

Operating across a broad range of industrial and commercial sectors around the globe, state-of-the-art production facilities include over £13m of recent investment on a new building and new manufacturing and test equipment equipment at its Rugby HQ to ensure it can meet future contract requirements. This enables Quartelec has the ability to work on any OEM-manufactured machine and / or equipment, including those built by its previous heritage companies including: GEC Machines, GEC Alsthom Large Machines, ALSTOM and Cegelec.

For additional details on the electrical contracting services available from Quartzelec or the manufacture, refurbishment and rewinding of electrical motors and generators, please call 44 (0) 1788 512512 or email Jody.Townsend@Quartzelec.com

Rue des Finettes 54

1920 Martigny

Switzerland